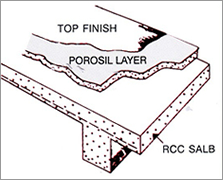

POROSIL is a light weight insulating aggregate insulation which is to be mixed with cement. It protects the building from the intensity of direct solar heat and lowers the room temperature by a minimum 6-8 degree and makes the covered area very pleasant. This product brings you to a new, simplified and cost effective solution for keeping building permanently cool structures as per your satisfaction.

| Layer thickness | U Value achieved in BTU/(Hr)(°)Ft) |

Consumption per Sq.ft. in kg. |

Approx. Reduction in Heat Transmission rate through RCC Slab in % |

|---|---|---|---|

| 2” (50mm) | 0.18 | 1.0 | 62 |

| 3” (75 mm) | 0.14 | 1.5 | 70 |

| 4” (100 mm) | 0.11 | 2.0 | 77 |

| #Considering rate of heat transmission U value = 0.47 BTU/(Hr)(0F)(Ft) 2 for 4" (100 mm) thick RCC slab. | |||

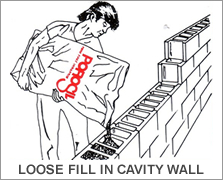

| Minimum compressive strength | 4 MPa per sq.mtr. |

|---|---|

| Maximum oven dry density | 480 kg per cu.mtr. |

| K value | 0.12 W/mK |

| R value | 1.2 per inch thickness |

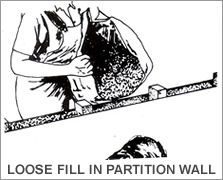

| Cavity thickness | U Value achieved in BTU/(Hr)(°F)Ft2) |

Consumption per Sq .ft. in kg. |

Approx. Reduction in Heat Transmission rate through Hollow Black wall in % |

|---|---|---|---|

| 2” (50mm) | 0.13 | 1.0 | 67.5 |

| 3” (75 mm) | 0.10 | 1.5 | 75 |

| 4” (100 mm) | 0.06 | 2.0 | 85 |

| #Considering rate of heat transmission U value = 0.40 BTU/(Hr)(°F)(Ft2) for 9" thick hollow block wall. | |||

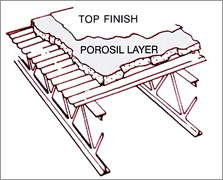

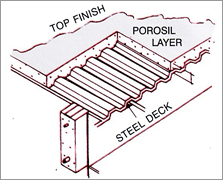

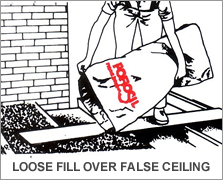

| Layer thickness | U Value achieved in BTU/(Hr)(°F)Ft2) |

Consumption per Sq. ft. in kg. |

Approx. Reduction in Heat Transmission rate through False/Suspended Ceiling in % |

|---|---|---|---|

| 2” (50mm) | 0.15 | 1.0 | 74 |

| 3” (75 mm) | 0.11 | 1.5 | 81 |

| 4” (100 mm) | 0.09 | 2.0 | 84 |

| #Considering rate of heat transmission U value = 0.58 BTU/(Hr)(0F)(Ft2) for A. C. Roof sheet of Industrial Building. | |||

| Basic Properties | ||

|---|---|---|

| K Value | : | 0.06 WLMK |

| R Value | : | 2.4 Per inch thickness |

| Bulk density | : | Max. 175kg per cubic metre |

Copyright © 2013 Porosil Insulation Pvt. Ltd.